- Home

- >

- Welding equipment

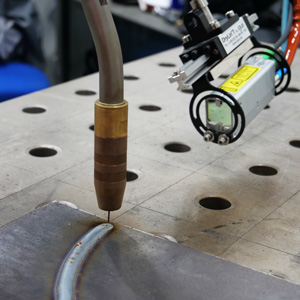

CAVITAR welding camera

In 2022, SERVISOUD and CAVITAR joined forces to offer their customers the distribution and integration of welding cameras on mechanised systems and welding carriages.

CAVITAR’s welding cameras are based on laser lighting technology that enables the visualisation of welding processes and their applications with a level of clarity and detail never seen before.

When combined with our SERVIBOT welding carriages, these welding cameras ensure increased productivity and enhanced welding quality control with live defect detection and improved welding traceability.

They can also be combined with our SERVICAM equipment for remote welding visualisation and teleoperation.

Elles peuvent également être associées à notre équipement SERVICAM pour la visualisation et la téléopération du soudage.

The CAVITAR C400 and C300 welding camera systems include a camera, integrated laser illumination, and optics adjustable to almost any welding application.

The welding camera uses advanced technology combined with laser illumination, enabling filming through the intense light from a welding arc.

The camera can be used to view different welding techniques: arc, laser, hybrid, plasma, welding robot, welding jib and additive manufacturing.

It also handles all major beam welding processes, including CO2 laser, fiber laser, diode laser, Nd: YAG laser, and electron beam techniques.

The welding camera can be used in a wide range of applications. It ensures the ergonomics and safety of welders by avoiding uncomfortable or dangerous positions and prevents the risks of exposure to the arc and toxic welding fumes.

Its compact design allows it to be implemented into the most challenging and space-restrictive remote applications. Supplied cooling channels and camera housing heat sinks ensure the camera’s durability in those harsh environments.

| Camera reference | C400 | C300 |

|---|---|---|

| Description | Compact welding camera for demanding environments with integrated lighting and cooling channels | |

| Max resolution (pixel) | 1440 x 1080 | |

| Max frame rate (fps)* | 70** | |

| Working distance (mm) | 150...300 | |

| View field | ||

| - working distance 150mm | 28 x 21 | |

| - working distance 200mm*** | 40 x 30 | |

| - working distance 250mm | 51 x 38 | |

| - working distance 300mm | 62 x 47 | |

| Size (WxHxL, mm3) | 38 x 48 x 99 | 30 x 45 x 99 |

| Weight (g) | 350 | 200 |

| Laser wavelength (nm) | 640 | |

| Laser class | 3R | |

| Camera interface | Gigabit Ethernet | |

| Gigabit Ethernet connector | M12, X-coded | |

| Power & IO connector | M12 | M8 |

| Cooling options | Passive: heatsink, heat conduction Active: air, liquid | |

* At full resolution, dependent on computer performance

** Up to 500 fps with reduced resolution (720 x 540 pixels) with high-speed version having USB3 interface

*** Factory default value

Would you like more information about the CAVITAR welding camera: advantages, examples of applications, technical specifications?

To visualise the images filmed by the CAVITAR welding camera, SERVISOUD has developed a portable and robust equipment for welding supervision and monitoring: the SERVICAM.

Combined with a CAVITAR C300 or C400 welding camera, the SERVICAM enables welders to visualise their weld pool in real time and record the generator parameters for data analysis. It also guarantees weld traceability thanks to its integrated software.

Access and download our resources