- Home

Welding Mechanisation – Mobile carriage

Welding mechanisation

Mechanisation allows you to automate your welding processes and thus increase your productivity, control the quality of the welds but also strengthen the safety of the welders.

Mechanisation allows you to automate your welding processes and thus increase your productivity, control the quality of the welds but also strengthen the safety of the welders.

▸ To increase arc-on time, that is, the actual welding time during a shift. This time is greatly increased on long weld applications to be made without stopping and restarting.

▸ To reduce risk of defects and required repairs.

▸ To optimise welding parameters and deposit rates while increasing welding speeds (for certain applications).

▸ Precise control of the weld quality. Weld beads are repeatable and more uniform, thus improving the aesthetics.

▸ SERVISOUD carriage reduce the rate of defects, specifically by reducing the number of stops and recoveries compared to manual welding.

▸ A precisely controlled welding operation via mechanisation ensures a better heat supply control and reduces thus arc deformations.

▸ Our welding solutions reduce exposure to heat, UV irridiation and fumes, as welders are positioned further from the torch.

▸ Thanks to their mobility and autonomy, carriage help welder to avoid a static position thus reducing arduousness and the risks of developing musculoskeletal disorders.

SERVIBOT is a range of products allowing to build your own mechanisation system for welding, cutting and other related processes.

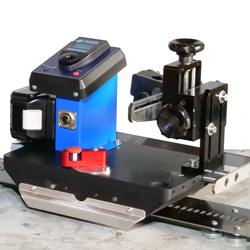

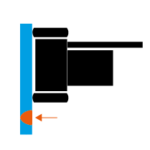

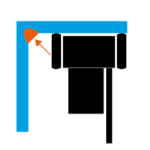

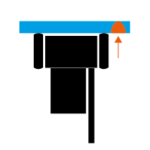

The range starts with a simple carriage equipped with a wheel or rail base and a central unit with a simple guiding interface. This carriage is completely modular as it can be upgraded with dual motorisation, positioning axes, remote control, welding or cutting kits…

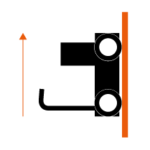

The welding carriages are connected, autonomous and programmable in all positions. All SERVIBOT system equipment are designed and manufactured in France by SERVISOUD.

The original range includes the GLUMAG® and TRACKMAG® welding carriages. They are self-contained and can be programmed in all positions. They are simple and intuitive to use and are compatible with all power sources and torches on the market.

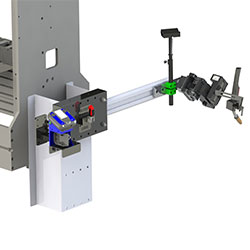

The progressive range is a 100% modular range that can be upgraded over time. Like the original range, it offers carriages for welding and related processes. But in addition, the carriages of the progressive range are equipped with a directional wheel base, remotely controlled by a wireless controller. The carriage is fully programmable and the operation is intuitive thanks to advanced path learning functions. The carriages can also incorporate additional options such as oscillation.

The specific range is a modular range of mechanisation. From standard and plug and play elements, the SERVIBOT specific range allows you to design 100% customised solutions to meet your needs.

During the 1990s, SERVISOUD designed and manufactured welding carriage and machines speciallydesigned for our customers.

In the 2000s, SERVISOUD designed its first standard range of welding carriage. As detailed below :

Naval

Metalwork

Energy

Road structure

Railway

Agriculture

Access and download our resources