- Home

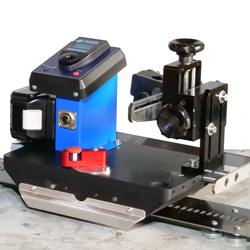

Welding Mechanisation – Mobile carriage

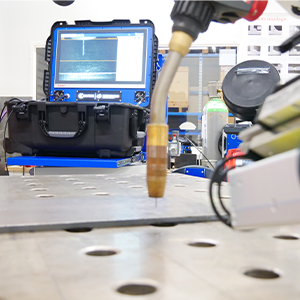

The SERVICAM range is a portable and robust supervision equipment, developed with our partner CAVITAR. This device centralises real-time visualisation, welding parameter recording, connectivity, and storage to ensure complete traceability of welds. It improves the quality, safety, and productivity of welders by allowing them to monitor the weld pool, identify defects, and analyse data even remotely.